© Ingo Mohr GmbH Spezial-Stahl Handel

SERVICE-HOTLINE

+49 (0) 21 54 - 81 20 820

We deliver selected material qualities in the following sizes:

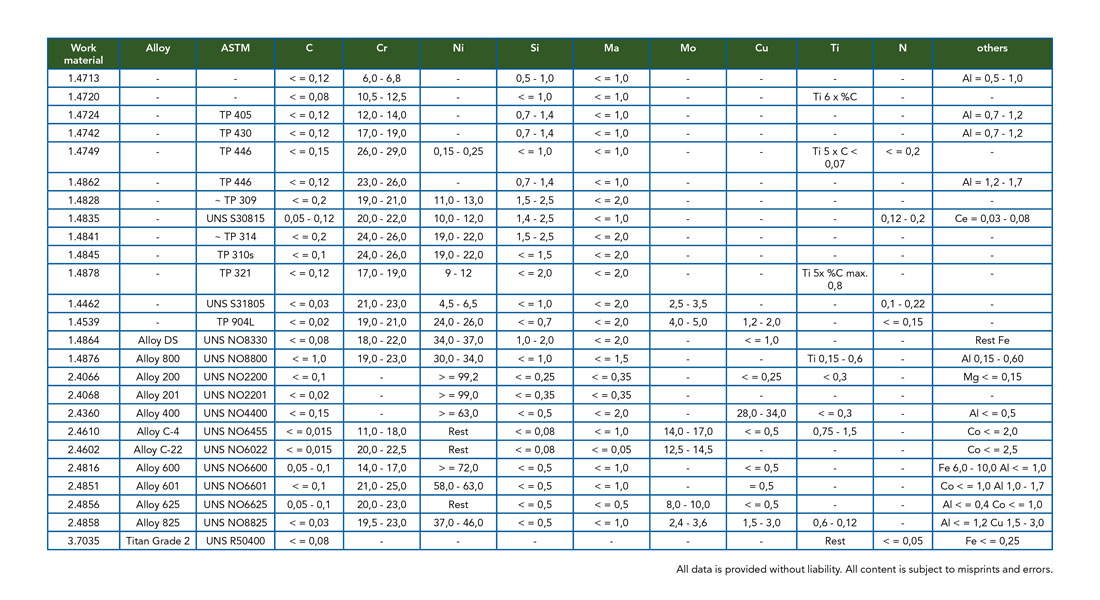

Work materials

Materials resistant to high heat

Heat-resistant steels with good stability properties under short- and long-term stress are particularly resistant to effects from hot gases and combustion products at temperatures above 550°C.

Material selection: The selection of a heat-resistant steel will depend on environmental conditions and mechanical properties. A high-alloyed and heat-resistant material may also have some disadvantages, e.g. brittleness. Ferritic steels: The main alloy element of these steels is chrome, supplemented by silicium and aluminium. These steels feature a non-deformed ferritic pattern. Its toughness when subjected to impulsive stress is relatively low. At temperatures above approx. 900°C, these steels develop coarse grits, which are associated with brittleness.

The additional alloying of more than 9% nickel creates steels with a non-deformed austenitic pattern. They are very tough and not sensitive to impulsive stress and sudden temperature changes. Other properties include:

|